SECURITY LABELS - PROTECTON POSSIBILITIES

Security Labels / Guard Labels

Labels to protect against tampering,

counterfeiting and returns fraud

Guard labels help prevent. Nobody can take them off and reattach them unnoticed, because they destroy themselves irreversibly when they are removed. Security labels are not undetectably interchangeable with imitations because they have features that make them unique and counterfeit-proof. Guard labels speak a clear language, because they signal unmistakably:

abuse of consumer rights. Security labels avert damage - especially also in e-commerce.

Labels with multiple benefits

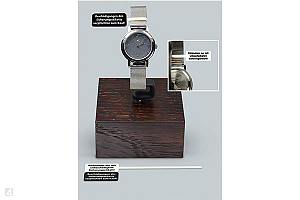

Guard labels can be produced as loop labels, but also in any other shape. Despite their special features, they can be printed with any data as standard labels using a thermal transfer printer. For example, a security label can be used for price marking or as a representative seal to guarantee the pristine original condition of a branded product. Individually combined, various protection factors result in a label with a unique character.Individual security labels / Guard labels

Custom-made solutions with various protection features

The security label - one-of-a-kind

The essential aspect of a security label is its inimitability. Every label wants to be safe in form and function from resourceful counterfeiters. That's why we hardly stock any standard security labels.Which type of label you choose depends entirely on your application. The full range of our production tools listed in our catalogue for shapes and dimensions is available for you to choose from.

Security Labels / Guard Labels made of self-destructing material

Material with sealing impact

Self-destructing material gives a security label seal character. The slightest attempt to open, remove and reposition an equivalent security label after first application will irrevertibly destroy it. Depending on its quality, it splits into layers, crumbles into minute particles or rips.Video demonstration PRIME-Guard Labels:

Self-destructing material with pattern effect

Video demonstration:

Self-destructing material with split effect

Which destruction effect occurs depends on the material used and how it is processed. For example, punching at certain, particularly sensitive points of the label shape can additionally support the already existing tearing tendency. The detachability of the label from the carrier web and its ease of application must not be restricted.

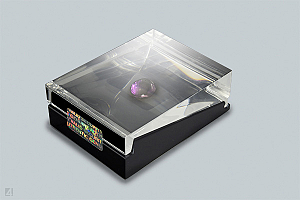

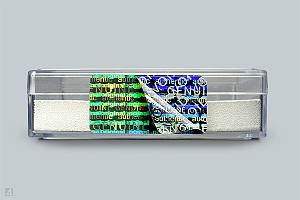

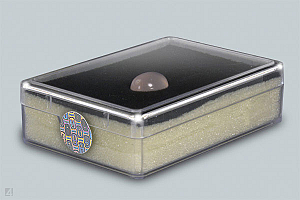

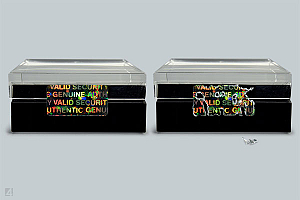

Security labels / Guard labels with hologram

Protection in a representative look

A hologram increases the counterfeit protection. So replacing the original security label by an imitation on possibly counterfeited goods is made difficult.Prefabricated holographic foils with a standardised security note or symbol, e.g. a lock, are used. For special security requirements it is possible to have individual hologram material produced. If you are not afraid of kost and effort, you can integrate your company logo or your own warning statement.

The use of holographic foil does not restrict the further use of the security label, for example in price labelling. Holographic patches can be printed on with standard thermal transfer printers in scratch-proof quality and resistant to ultrasonic bath.

Security Labels / Guard Labels with blacklight-sensitivity

Hidden counterfeit protection

Blacklight-sensitive print on a security label remains invisible in daylight and artificial light. As known from the authenticity control of money bills, black-light sensitive areas can only be detected under a special lamp. In principle, blacklight-sensitiv printing can be overprinted with individual data via thermal transfer printer.

Blacklight-sensitive printing is done with prefabricated foils. Three different film types are possible:

The first film type shows a readable print image under normal light conditions, like any standard print. In addition, a standardized pattern visible only under black light appears within the printed areas.

The second option uses a film that prints exclusively blacklight-sensitive. The printed image created in this way, e.g. company logos or texts, can therefore only be seen illuminated accordingly.

As a third version, the complete security label is covered with a blacklight-sensitive laminate. Blacklight then illuminates the entire label surface, but not the data imprint.

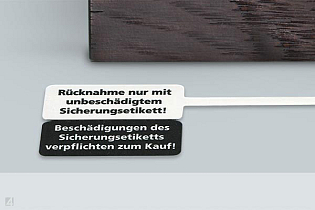

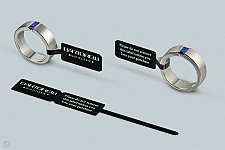

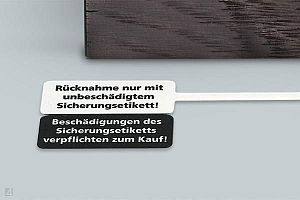

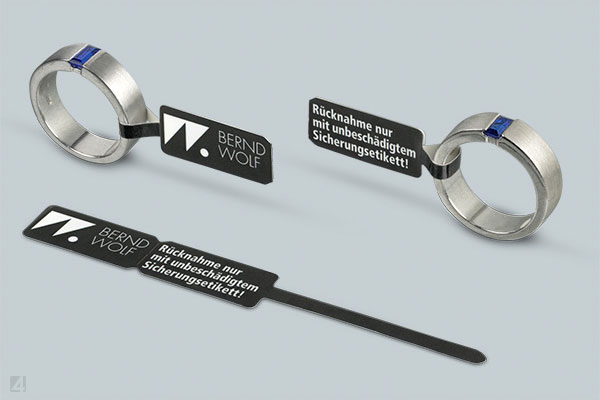

Security Labels / Guard Labels with warning instruction

Protection through clear words

Returning worn or used goods with reference to the right of return and reclaiming the price paid is widespread, especially in e-commerce. Here plain text helps to put bazen consumers in their place. A warning message on the security label clarifies unmistakably: Anyone who removes the label exceeds his authority and commits himself to purchase.If the label is too small for text, a symbol, e.g. a security lock, can also signal the seal character of the label. This makes it immediately clear that if the security label is missing or damaged, the consumer has forfeited his right to a return.

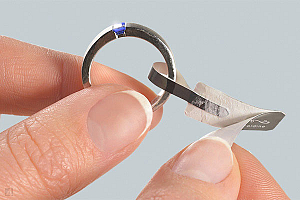

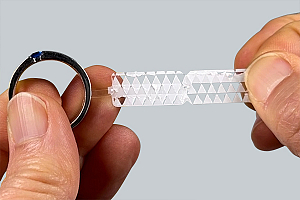

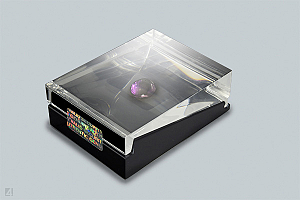

Security Labels with Pattern Effect - PRIME-Guard Labels

When a PRIME-Guard Label is applied, the white permanent adhesive bonds between the transparent label areas to form an almost opaque layer. An attempt to separate again the firmly adhering adhesive surfaces of the label once closed causes the adhesive film to tear in a defined structure. The label areas show a transparent triangle pattern. It cannot be revised, not even by fitting the separated surfaces together exactly. This makes every manipulation attempt obvious and verifiable.

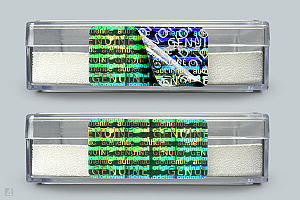

Security Labels with Splitting Effect

When first attached, the permanent adhesive bonds the adherent label surfaces so tightly that an attempt to reopen the label will split the material into layers.The split label areas are unglued, so they do not stick and cannot be rejoined immediately. The label cannot be easily reapplied but is permanently damaged.

Guard Labels based on Destruct material with a split effect act as a preventive measure against fraudulent reapplication of labels once removed to goods that have already been used.

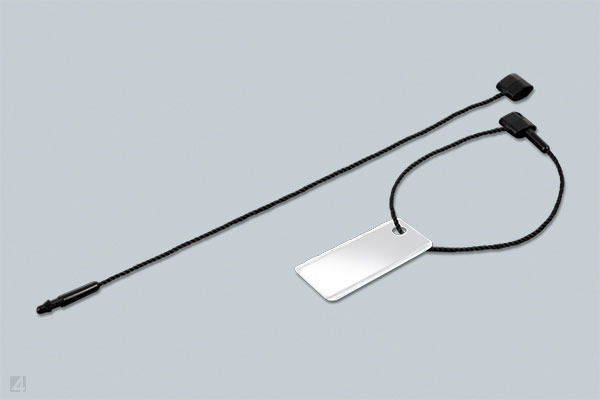

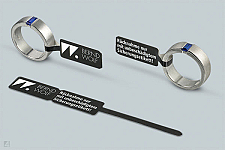

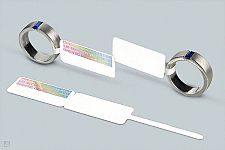

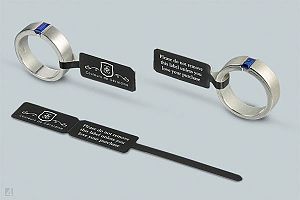

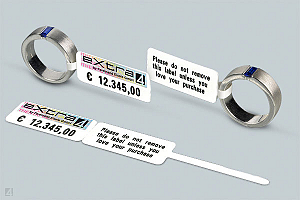

Threads with the security plus

For increased security requirements, we can also recommend the use of security threads from our range of fastening accessories. The threads consist of a tear-resistant textile cord and have a snap lock. Once closed, the special mechanism cannot be opened again. The thread must be cut to remove the label.Security threads are used with self-adhesive tags or thread labels. They are particularly representative when combined with self-adhesive thread labels of the WrapTag type. With this type of label, two additional transparent areas wrap the label as soon as it is folded.